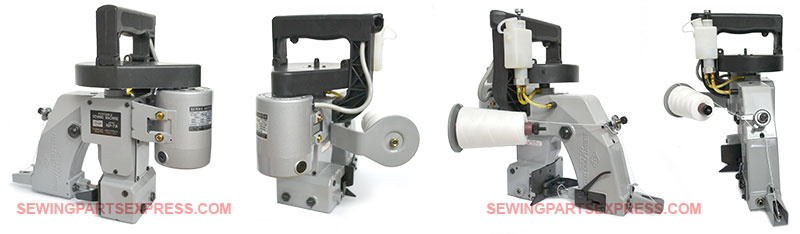

Stitch Skipping on NLI Newlong NP-7A:

Most of the time the needle is inserted wrong. The needle can rotate inside the socket. The scar needs to point upwards. (refer to the manual)

When the stitch of a NLI Newlong Industrial NP-7A is skipping the needle is lightly bend and the distance between the needle and the looper is out of range.

Solution:

First replace the needle of your NLI Newlong Industrial NP-7A

Oiling a NLI Newlong NP-7A:

To keep your machine in best condition, everytime you use your Newlong Industrial NLI NP-7A needs to be oiled. Besides oiling via the build in oil pump, also some bushings of your Newlong Industrial NLI NP-7A need to be oiled. After a day of work always clean your Newlong Industrial NP-7A with high pressure air and / or a brush.

Maintenance: when to oil the NLI Newlong Industrial NP-7A

1. Keep off dust or foreign matter when to fill oil (They may cause jamming of the piston and the check valve).

2. Rate of discharge is fixed and not adjustable (0.08cc per push).

3. At high temperatures, grease may run along points ○A . This is normal, grease being used when the lubricator was assembled in our plant.

4. The oil reservoir of the Newlong Industrial NLI NP-7A is made of high density polyethylene. Keep off fire and refrain from using organic, benzene,

or xylene chemicals for cleaning. Check periodically for correct working of the pump. (Repeat oil feed and look at the oil through the discharge pipe).

Cleaning:

Clean the Newlong Industrial NLI NP-7A at the end of the dayʼs work, and oil the bushings, shaft, etc. that are not lubricated by a lubricator.

Wipe dust and other foreign matter off the: Feed Dog teeth, Looper, and Throat Plate eyelet where they are easily gathered.

Care should be taken to keep the Newlong Industrial NLI NP-7A free from dust, especially when to leave it unused for some time.

Stitch Skipping on NLI Newlong Industrial NP-7A:

When the stitch of a NLI Newlong NP-7A is skipping the needle is lightly bend and the distance between the needle and the looper is out of range.

Position of Needle and Looper (Fig.11)

The Looper must pass the concave part of Needle with clearance of 0.1 mm as shown in Fig.11.

Adjustment of the clearance can be done after loosening the screw of Looper Rocker.

[NOTES ON CARRYING AND STORAGE your NLI Newlong NP-7A Bag Closer Sewing Machine]1. Carry the NNLI Newlong NP-7A in a storage box.

2. After the use of the NLI Newlong NP-7A, remove the plug, clean the dirt, take the thread from your NLI Newlong NP-7A and then put it into

a storage box. We suggest you to use a soft brush to clean the rear of the NLI Newlong NP-7A.

3. Never store your NLI Newlong NP-7A under the sunlight dried or wet condition.

Threading

The NLI Newlong NP-7A is delivered by the manuracturer threaded to show you the proper threading, which is shown in the NLI Newlong NP-7A operator manual.

Please follow the guide.